Company News

How can we guarantee 100% silicone ice mold non-toxic and tasteless that can rest use Hanchuan industry

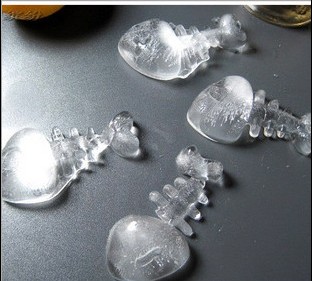

Silicone ice mold, which was also known as silicone ice grid, sales in the market at present. The materials are basically using the 100% food grade silicone rubber material, non-toxic and tasteless, low carbon environmental protection, adn basically can guarantee the health of consumers. But there are a lot of ice trays on the market was not using food grade materials silicone, the ice tray is unable to guarantee the health of consumers, so everyone in the purchase of ice tray should pay more attention to what material the product is made of. This is the key.

Also some silicone ice mold manufacturers in order to save costs, a number of low cost silicone materials added in the silica gel in the raw materials. And even ice grid products are not after two curing, this product is unable to guarantee 100% silicone ice mold non-toxic tasteless. Consumers must not yield to the temptation of cheap, it is necessary to look for the brand manufacturers, silicone ice tray and all must again after two vulcanization can ensure the quality of products, the role of vulcanized silicone rubber two times: with peroxide curing, peroxide decomposition caused by polymer reaction after the production of low molecular compounds (such as benzene and benzoic acid etc.) exist in the rubber will influence the mechanical properties of rubber, silicone rubber in the first heating after forming, the crosslinking density is not enough, must be two times to increase the density of vulcanized silicone rubber, tensile strength. Resilience, density, hardness, degree of swelling, heat stability than the first vulcanization is greatly improved, the residue is completely evaporate. So after silicone ice die two times after vulcanization, consumers can rest assured that the use of 100%!

Related Articles

- Eiffel Tower silicone tea infuser Export France Carrefour by Hanchuan exclusive design !

- France customer ordered our Homewares Skull and Crossbones Ice Cube Tray from Hanchuan

- BWH company ordered our silicone handbag from hanchuan Ltd

- Germany VS Brazil gifts clients would like to order Hanchuan silicone ice shot glass mold

- England customer ordered our silicone Stops boiling pots from Hanchuan

- BONNEVIE ordered our Dog Shaped Silicone Durable Oven Mitt from Hanchuan

- Alfie ordered our Silicone Pet Expandable/Collapsible Travel Bowl from hanchuan

- Kitchen Kritters ordered our fish shaped silicone oven mitts from Hanchuan

- What are the Shenzhen silicone ice tray mold factory? What is the main mold product development?

- Silica gel factory:Holland gift purchasing silicone ice tray, the first choice is Hanchuan usse brand